347 Spiral Wound Gaskets

Item No.:ZD-G1206/347

Description:

347 (UNS S34700) is a stabilized

stainless steel which offers as

its main advantage an excellent

resistance to intergranular

corrosion following exposure to

temperature in the chromium

carbide precipitation range from

800 to 1500 oF (427

to 816 oC). Alloy 347

is stabilized by the addition of

columbium and tantalum.

347 stainless steel is also

advantageous for high

temperature service because of

its good mechanical properties.

347 offers higher creep and

stress rupture properties than

SS304.

In order to adapt to the strict request, we according to requirements provide 347 spiral wound gaskets. According to the flange structure, spiral wound gasket with or without 347 inner rings, 347 hoop, CS outer ring. 347 inner ring as the same as 347 strip.

General

Properties:

![]() 347 is stabilized stainless

steel;

347 is stabilized stainless

steel;

![]() 347 is stabilized by the

addition of columbium and

tantalum.

347 is stabilized by the

addition of columbium and

tantalum.

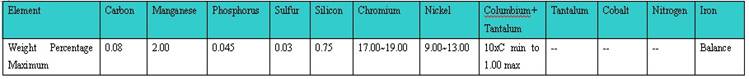

Chemical

Composition:

Resistance to

Corrosion:

![]() 347

is preferable for aqueous and

other low temperature

environments then 321 stainless

steel;

347

is preferable for aqueous and

other low temperature

environments then 321 stainless

steel;

![]() 347

is used primarily in high

temperature applications where

high resistance to sensitization

is essential, thereby preventing

intergranular corrosion at lower

temperatures;

347

is used primarily in high

temperature applications where

high resistance to sensitization

is essential, thereby preventing

intergranular corrosion at lower

temperatures;

![]() 347 have excellent resistance

applications in intergranular

corrosion.

347 have excellent resistance

applications in intergranular

corrosion.

Stress Corrosion

Cracking:

![]() Alloy 347 is particularly useful

under conditions which cause

polythionic acid stress

corrosion of non-stabilized

austenitic stainless steel, such

as SS304;

Alloy 347 is particularly useful

under conditions which cause

polythionic acid stress

corrosion of non-stabilized

austenitic stainless steel, such

as SS304;

347 have good elevated temperature oxidation resistance.

Physical

Properties:

![]() The

stabilized 347 is generally

without magnetic;

The

stabilized 347 is generally

without magnetic;

![]() The elevated temperature creep

and stress rupture strengths of

the stabilized steels are higher

than 304 and 304L;

The elevated temperature creep

and stress rupture strengths of

the stabilized steels are higher

than 304 and 304L;

![]() 347 have excellent toughness at

room and sub-zero temperatures;

347 have excellent toughness at

room and sub-zero temperatures;

![]() The fatigue endurance limits of

347 is approximately 35% of its

tensile strengths.

The fatigue endurance limits of

347 is approximately 35% of its

tensile strengths.