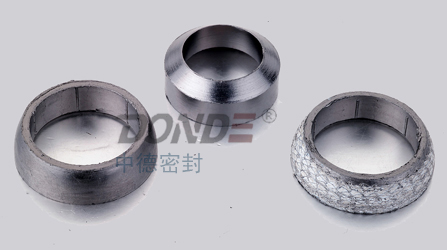

Die-formed

Flexible Graphite Ring For Exhaust

Item NO:ZD-RG2100

Description:

Die-formed Graphite Rings For Exhaust are made of low-sulphur expanded

graphite with metal wire fillers or binders. The fillers enhance the

strength of the graphite rings.Die-formed Graphite Rings For Exhaust are compressed

in precise moulding tools to the required density.It is mede from the

high purity of the material (>99%), no special corrosion protection is

required. In general, Die-formed Graphite Ring has square section and

also has V-shaped and wedge-shaped section.

The sphere cushion and able to bear the sealed material

graphite of high temperature to pass the special place the metal silk

screen pay attention to die casting but succeed, There is very good

compression elasticity, the system is idea that exhaust First-selected

special-purpose seal.The sphere cushion surface is dealt with by the

ceramic, have good lubrication and seal even more Result, make the

vehicle dispel and rub sound completely in advancing, domestic head of

this technology Create!

Stocked Molds:As we DONDE supply this kind

graphite rings to many factory and we work with them for a long time,we

nearly have molds for all size.It will save time and cost of our new

customers.The lead time will be very short.

Main Specification:

|

Testing Items |

Numerics |

|

Carbon concentration |

99% |

|

Sulfur concentration |

<1000ppm |

|

Chlorine concentration |

<45ppm |

|

Recovery |

>10% |

|

Temperature |

-200~+580℃(Non oxidizing condition-200~+800℃) |

|

Pressure |

=<35MPa |

|

Linear Velocity) |

10m/s |

|

PH |

0-14 |

|

Density |

1.4-1.6g/cm3 |

|

Size |

ID:6mm to 900mm OD:12mm to 1100mm |

Warning: Gasket

materials should never be recommended when both the temperature and the

pressure are at the maximums listed. Properties and applications shown

are typical. No application should be undertaken by anyone without

independent study and evaluation for suitability. Never use more than

one gasket in one flange joint, and never reuse a gasket. Improper use

or gasket selection could cause property damage and/or serious personal

injury. The data reported is a compilation of field testing, field

service reports and/or in-house testing. While the utmost care has gone

into publishing the information contained herein, we assume no

responsibility for errors. The information and specifications

contained in this website are subject to change without notice. This

revision cancels and obsoletes all previous editions.